Low Temperature Sludge Dryer

ConsultationProduct overview: Low temperature heat pump dryer, efficient & safe

Product features: 10% water content, >80% volume reduction; 1KWH:4.2KG(Electricity VS Water removal) Twice the industry standard; Odor free without deodorization; No heat loss, 100% heat use; Safe in low temperature condition, no raising dusts;

System Feature

≤10%Water content, Volume reduction>80%

Sludge volume further reduction, dry sludge water content ≤10%-50% adjustable, reduction>80%

1:4.2 Electricity VS Water removal

Innovative 4 effect Condensation dehumidification and drying technology, 1 KWH electricity can remove 4.2KG water

Odor free without deodorization

The whole system adopts closed running design, no odor out, no need to install expensive deodorization system as a secondary investment. It can be directly installed in the plant for centralized disposal, and the condensate can be directly discharged without secondary treatment.

No heat loss, 100% heat use

The system is combined with heat pump heat recovery technology, which has no heat loss and better working efficiency. It is different from the open drying method with continuous moisture removal and continuous high temperature heating.

Safe in low temperature condition, no raising dusts

Fully closed 40-75 ℃ low temperature operation, no need for nitrogen filling operation, oxygen content in drying process is less than 12%, dust concentration is less than 60g / m3, particle temperature is less than 70 ℃, no potential dust and explosion, discharge temperature is less than 50 ℃, no need for secondary cooling, and it can be directly stored.

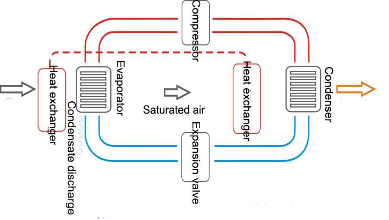

Low Temperature Sludge drying principle

This low-temperature drying system uses the principle of heat pump dehumidification to reduce the volume of the wet sludge on the mesh belt by the way of convection hot air drying. The whole system is fully closed design, and the drying hot air has no heat loss.

![1576829052506769[1]](/en/Uploads/image/20200319/1584593064809174.jpg)

Using the refrigeration system to cool and dehumidify the wet air from the drying chamber, and recover the latent heat of moisture condensation to reheat the dry air. It is the combination of dehumidification (dehumidification) and heat pump (energy recovery), and it is the recycling of energy in the drying process.

Technical analysis

Application

The dryer can directly dry wet sludge with water content of 83% to water content of 10% - 30%, with reduction up to 90%, effective sterilization 90%, low energy consumption, pollution-free, widely used in municipal sludge and industrial sludge (printing and dyeing, papermaking, electroplating, chemical industry, leather, pharmaceutical, etc.) In the later stage, the dry sludge can be treated by gasification, blending, composting or building materials.

Innovative Technology

The 4 effect condensation dehumidification and drying technology is currently the most advanced sludge drying technology. It has obvious advantages such as lower air temperature, better drying capacity and efficiency, more economical operation cost, etc. The comprehensive dehumidification performance ratio is 4.2kg water removed by 1KWH electricity, which is twice the industry standard.

![1576829834757272[1]](/en/Uploads/image/20200319/1584595270471863.jpg)

Sludge Handling Process Flow

![1576831324153836[1]](/en/Uploads/image/20200319/1584596053859530.jpg)

Advantages of Low Temperature Belt Sludge Dryer

Comparison-Middle Temp Belt Dryer

Item | Middle Temp Belt Dryer | Low Temp Belt Dryer |

Sludge convey | Stainless steel mesh belt | Stainless steel mesh belt |

Heat source | Coal, oil, anaerobic digested gas | Hot water |

Temp | 110-150℃ | 40-75℃ |

Method | Steam, Hot air | Heat pump |

Dehumidification | Open (dehumidification + condensation) | Closed condensation(no heat loss) |

Shape | Extrusion, slitting, granulation | Extrusion, slitting, granulation |

Waste gas | Need expensive deodorization system | No |

Cooling of outlet material | Need cooling | Direct |

Consumption | Heat(2880K/kgH2O) +Electricity(0.1 kwh/ kG H2O) | Electricity(025kwh/kgH2O) |

Support | Complex, expensive | Simple, easy operation |

Comparison-Traditional Sludge Dryer

| Item | Rotary drum | Rotary Disc | Thin layer evaporator | Hollow paddle | Low Temp Belt Dryer |

| Drying Temp | 200-300℃ | >150℃ | >150℃ | >150℃ | 40-75℃ |

| Method | Thermal convection | Heat conduction | Heat conduction | Heat conduction | Hot ait circle |

| Heat supply | Hot air, gas | Steam, heat oil | Steam | Steam、heat oil | Heat pump |

| Raising dust | Extremely high | High | High | Extremely high | No |

| Security | High operation temp | High temp, nitrogen required | High operation temp | High operation temp | Low temp |

| Waste gas | Need expensive deodorization | Need expensive deodorization | Need expensive deodorization | Need expensive deodorization | No |

| Heat consumption KJ/Kg water | 3400 | 2800 | 2300 | 2800 | No |

| Electricity consumption Kwh/kg water | 0.7 | 0.5 | 0.53 | 0.4 | 0.25 |

| Model | MYB600SL | MYB1200SL | MYB2400FL | MYB4800FL | MYB7200FL | MYB9600FL | MYB14400SL |

| Water removal/24h | 600kg | 1200kg | 2400kg | 4800kg | 7200kg | 9600kg | 14400kg |

| Water removal/h | 25kg | 50kg | 100kg | 200kg | 300kg | 400kg | 600kg |

| Power | 8kw | 15kw | 26kw | 52kw | 75kw | 104kw | 156kw |

| Heat Pump Module | 1 | 1 | 1 | 2 | 3 | 2 | 3 |

| Compressor | 1 | 1 | 4 | 8 | 12 | 8 | 12 |

| Cooling method | Tap water | Fan cooling | Fan cooling | Cooling tower | |||

| Cooling water flow △t=15℃ | 0.2m³/h | 0.4m³/h △t=20℃ | // | // | // | // | 9m³/h |

| Dimension mm | 2625*1277*1850 | 3170*1580*2080 | 3760*2190*2420 | 6460*2190*2420 | 9160*2190*2420 | 7900*3110*3200 | 11150*3110*3200 |

| Structure | Complete | Complete | Complete | Assembly | Assembly | Assembly | Assembly |

| Weight T | 1.5 | 2 | 3.2 | 5.8 | 8 | 9.1 | 12.3 |

| Refrigerant | R134a | ||||||

| Power supply | (220V\380V\440V)/3H/50Hz(60Hz) | ||||||

| Drying temp | 48 - 56℃/6S ~ 80℃ | ||||||

| Control | Touch screen+PLC | ||||||

| Water content of dry sludge | 10-50% adjustable | ||||||

| Shape | Slitting or extruding | ||||||

| Model | MYB19200SL | MYB24000SL | MYB28800SL | MYB33600SL | MYB38400SL | MYB43200SL | MYB48000SL |

| Water removal/24h | 19200kg | 24000kg | 28800kg | 33600kg | 38400kg | 43200kg | 48000kg |

| Water removal/h | 800kg | 1000kg | 1200kg | 1400kg | 1600kg | 1800kg | 2000kg |

| Power | 208kw | 260kw | 312kw | 364kw | 416kw | 468kw | 520kw |

| Heat Pump Module | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Compressor | 16 | 20 | 24 | 28 | 32 | 36 | 40 |

| Cooling method | Cooling tower | ||||||

| Flow △t=15℃ | 12m³/h | 15m³/h | 18m³/h | 21m³/h | 24m³/h | 27m³/h | 30m³/h |

Dimension mm | 14400*3110*3200 | 17650*3110*3200 | 20900*3110*3200 | 24150*3110*3200 | 27400*3110*3200 | 30650*3110*3200 | 33900*3110*3200 |

| Structure | Assembly | Assembly | Assembly | Assembly | Assembly | Assembly | Assembly |

| Weight T | 15.5 | 17.7 | 21.9 | 25.1 | 28.3 | 31.5 | 34.7 |

| Refrigerant | R134a | ||||||

| Power | (220V\380V\440V)/3H/50Hz(60Hz) | ||||||

| Drying temp | 48 - 56℃/6S ~ 80℃ | ||||||

| Control | Touch screen+PLC | ||||||

| Water content of dry sludge | 10-50% adjustable | ||||||

| Shape | Slitting or extruding | ||||||

- Last article: no more;

- Next article: Low Temperature Waste Heat Sludge Dryer